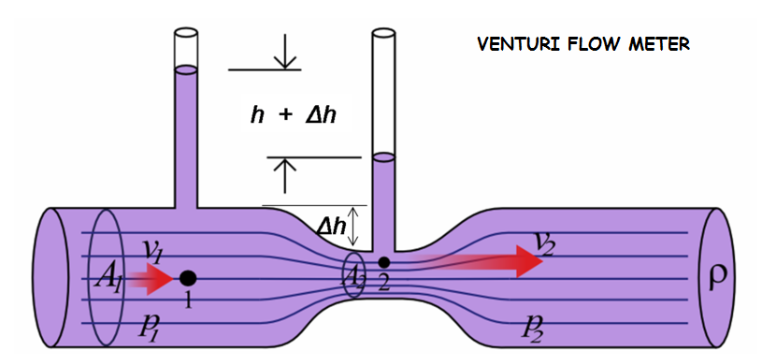

Venturi tube flow meter

Working principle:

The fluid whose flow rate is to be measured enters the entry section of the venturi meter with a pressure P1.

As the fluid from the entry section of venturi meter flows into the converging section, its pressure keeps on reducing and attains a minimum value P2 when it enters the throat. That is, in the throat, the fluid pressure P2 will be minimum.

The differential pressure sensor attached between the entry and throat section of the venturi meter records the pressure difference(P1-P2) which becomes an indication of the flow rate of the fluid through the pipe when calibrated.

The diverging section has been provided to enable the fluid to regain its pressure and hence its kinetic energy. Lesser the angle of the diverging section, greater is the recovery.

Applications:

The Nervuri tube flowmeter can successfully measure the following fluids:

1. GAS

Gas (blast furnace gas, coke oven gas, water gas, producer gas, oil gas)Natural gas (dry well gas, associated gas in oil fields, including high-humidity natural gas and non-clean natural gas containing other impurities)Air, including water, solid particles, and air containing other suspended matterVarious hydrocarbon gases, including wet HC gasesVarious rare gases such as hydrogen, helium, argon, oxygen, etc.Wet chloride gasFlue gas

2. STEAM

Saturated Vaporsuperheated steam

3. LIQUID

Water, including clean water, sewage, oily, vinegar, sandy water Toluene, methanol Various aqueous solutions, including salts, aqueous alkali solutions, etc.

4. SPECIAL FLUID

Oil + HC gas + water + sand Aerated water, such as H2O + air; H2O + CO2, etc.

Advantages of venturi meters

1. Less changes of getting clogged with sediments2. Coefficient of discharge is high.3. Its behaviour can be predicted perfectly.4. Can be installed vertically, horizontally or inclinded.5. Low pressure drop (around 10% of Δp)6. Lower sensitivity to installation effects than orifice plates7. Less susceptibility to damage8. More suitable for gas flows with entrained liquid9. Comprehensive standards (ISO 5167)

Limitations of venturi meters

1. They are large in size and hence where space is limited, they cannot be used.2. Expensive initial cost, installation and maintenance.3. Require long laying length. That is, the veturimeter has ti be proceeded by a straight pipe which is free from fittings and misalignments to avoid turbulence in flow, for satisfactory operation. Therefore, straightening vanes are a must.4. Low turndown (can be improved with dual range Δp cells)5. Greater cost to manufacture6. Greater susceptibility to “tapping errors” in high Reynolds number gas flows owing to the high velocity fluid passing the pressure tapping at the throat.7. Less experimental data than orifice plates

- Previous Product:Wedge type flow meter

- Next Product:Orifice plate