Thermal mass flow meter

Overview

Thermal gas mass flow meters are used in the field of process control. It does not require temperature and pressure compensation to directly measure the mass flow of the fluid. Its outstanding features are: no moving parts; low pressure loss; wide range ratio; high precision; high reliability; simple installation and convenient operation. Orifice plates and differential pressure flow meters can be fully replaced in all areas.

Working principle

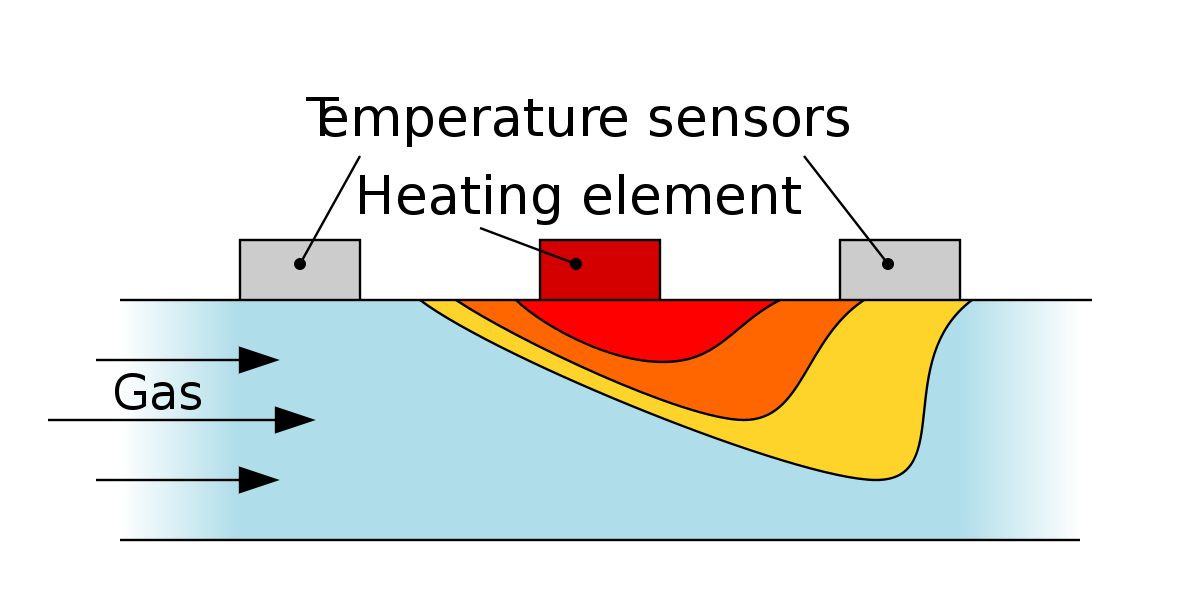

The thermal gas mass flowmeter adopts the principle of thermal diffusion. The thermal diffusion technology is a technology with excellent performance and high reliability under severe conditions. The typical sensing element includes two thermal resistors (platinum RTD) and one is a speed sensor. One is a temperature sensor that automatically compensates for changes in gas temperature. When the two RTDs are placed in the medium, the speed sensor is heated to a constant temperature difference above ambient temperature and the other temperature sensor is used to sense the medium temperature. The mass flow of gas through the velocity sensor is calculated by the amount of heat transfer from the sensing element. As the gas rate increases, the amount of heat that the sensor delivers to the medium increases.

1. All products are designed with no moving parts. The sensor will not be blocked due to dirty media or media particles.

2. Wide range ratio of 100:1, sensitive to low flow No multi-level measurement is required, suitable for various ranges on site.

3. There is almost no pressure loss, which overcomes the shortcomings of the traditional differential pressure method that cannot be measured due to low pipeline pressure.

4. Handle various practical problems of the user (such as unsatisfied installation of straight pipe sections, changes in components, poor measurement results, etc.). The component changes can be corrected, the sensor can be cleaned online, and the insertion length can be adjusted freely.

5. Sensor optional single / multi-point to meet a variety of different use requirements and high-precision measurement.

6. Sensor plug-in or online installation Reduce installation costs and be suitable for measurement of various pipe diameters.

Features

1. Setting of different gas coefficients

2. Display zero clear

3. Output analog correction

4. Multi-point nonlinear curve correction

5. Wide range ratio is greater than 100:1

6. Large diameter small flow measurement accuracy is higher

7. On-site can set the meter

8. Package sensor close to zero pressure loss

9. Not sensitive to vibration

10. Straight pipe requirements are smaller

11. Measured value is independent of pressure, true mass flow detection

12. Using expert algorithms to achieve high precision and stability of the instrument

13. Less than one second response time

14. Liquid crystal display with instantaneous cumulative dual display, no need to switch

- Previous Product:DXF-1-980 series insertion thermal mass flow meter